Digital transformation

initiatives

Digital transformation

initiatives

By driving a digital transformation strategy

that integrates digital technologies and physical operations,

we will contribute the overall competitiveness of the steel

industry while undergoing our own operational transformation.

The steel industry as a whole faces a multitude of challenges that need to be addressed for the future, including the advent of a decarbonized society and the resilience of the supply chain in consideration of geopolitical risks. As a company responsible for distribution and processing of steel products, Metal One is committed to leverage digital technologies more extensively and combine them with physical operations. Through this approach, we will not only embark on our own business transformation but also create new value to meet the growing complexity of these challenges, contributing to enhancing the overall competitiveness of the steel industry.

DX VISION

Enhancing trading & distribution capabilities through Lean Operations,

and offering new value through Solution Businesses.

As part of our commitment to addressing the increasingly complex industrial challenges, we have set two key pillars for transformation: enhancing our own trading & distribution capabilities through Lean Operations, and expanding Solution Businesses that solve customer issues through new value propositions.

expanding overseas markets

and so on

Lean operations

Business Process Automation

Smart sharing, and so on

Solutions businesses

Metal X®

Metal X UP®, and so on

Strengthening IT and digital infrastructure

Key performance indicators

Workload time

Asset size

Effect on business P/L

Establishing new business models

that solve customer issues

Lean operations

Business process automation

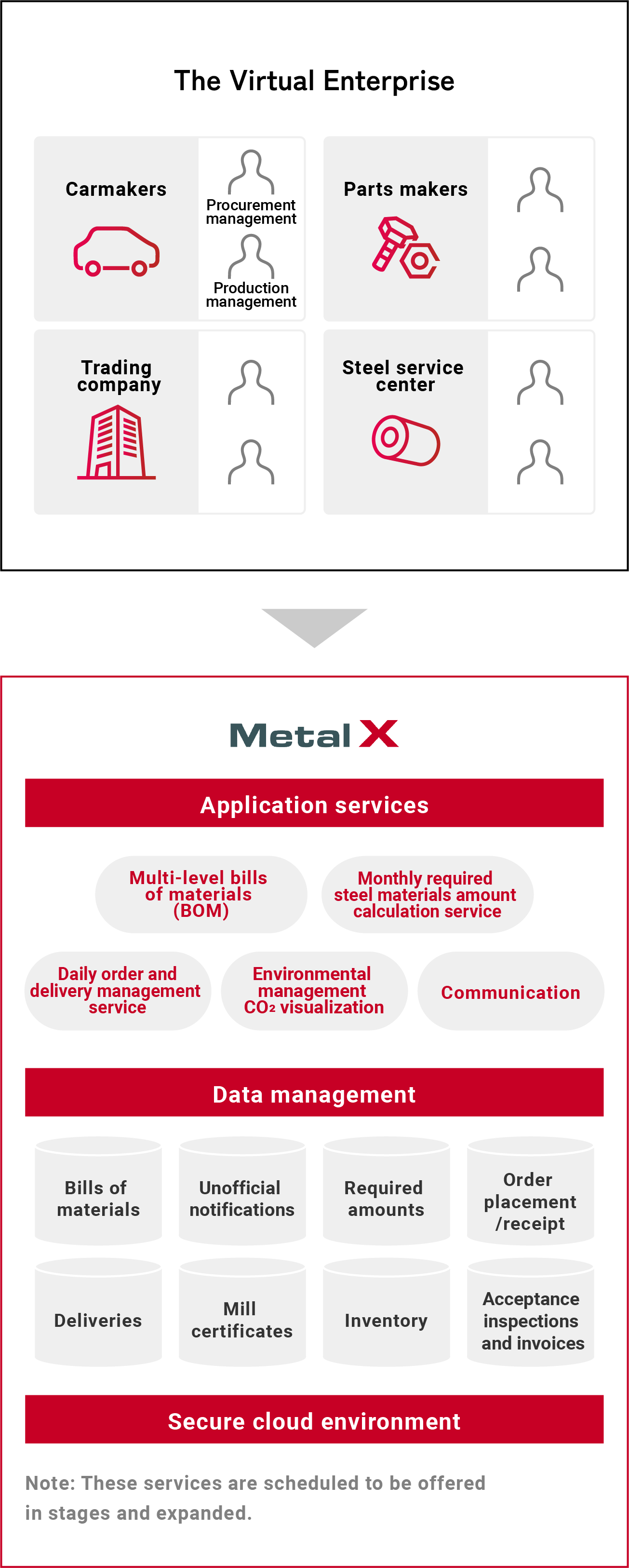

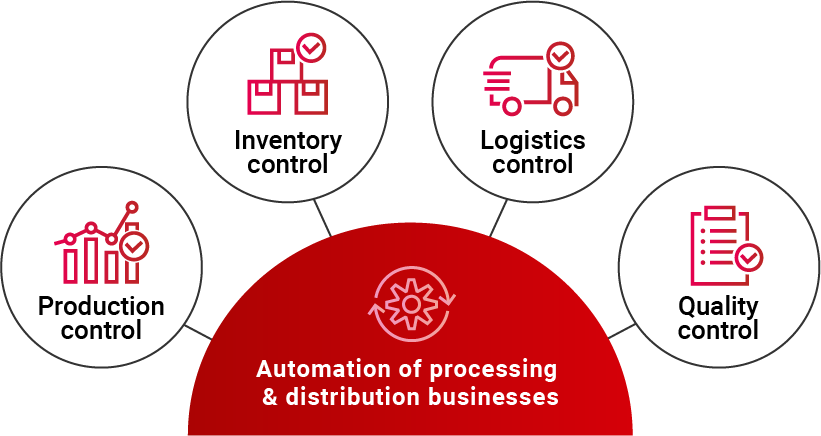

To enhance customer value and improve the overall competitiveness of the supply chain, we are committed to automating standardized operations as much as possible and optimize operational efficiency and increase productivity through the utilization of various digital tools. Additionally, these initiatives enable us to identify operational challenges and drive improvements in business operations that extend beyond the utilization of tools.

distribution businesses

transactions

Smart sharing

“Smart Shared services” differs from merely aggregating operations in the usual form of shared services. Instead, it focuses on devising optimized business processes using digital technologies and the specialized expertise of Group personnel to automate operations and augment efficiency.

The finance, accounting and credit operations of Group companies that utilize the standardized ERP system were consolidated on October 1, 2023.

Shared Services Department

Carrying out operations efficiently using shared digital tools

Solutions businesses

Metal X®

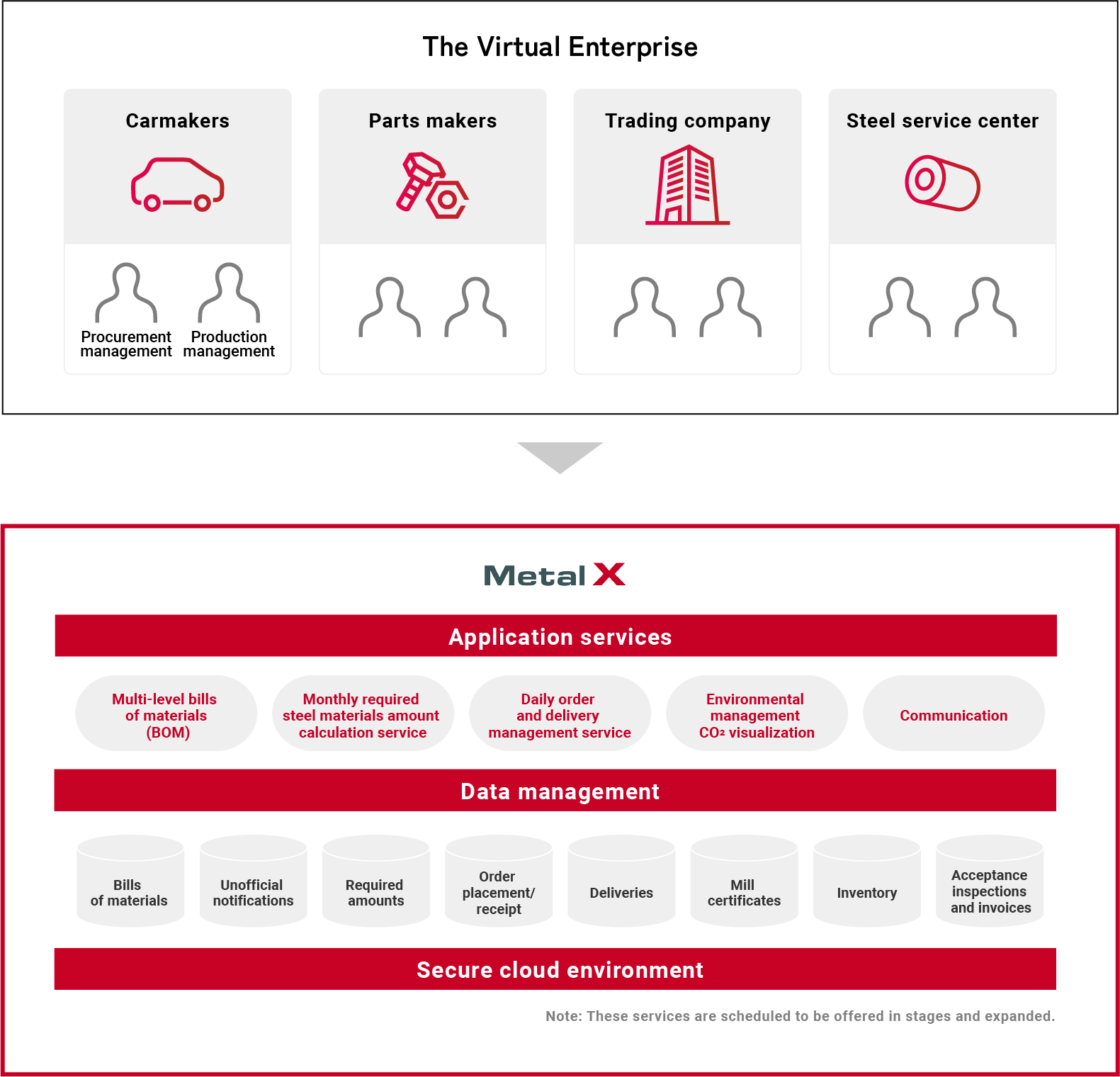

We have developed a digital platform called “Metal X®” to streamline and enhance inter-company communication and operations in the supply chain of automotive steel sheet distribution. By treating the companies involved as a single entity and sharing data through the same system, Metal X enables efficient and seamless communication. It includes features such as automatic calculation of the required steel material based on the parts list information from automotive components to steel materials, as well as production schedule of automotive manufacturers.

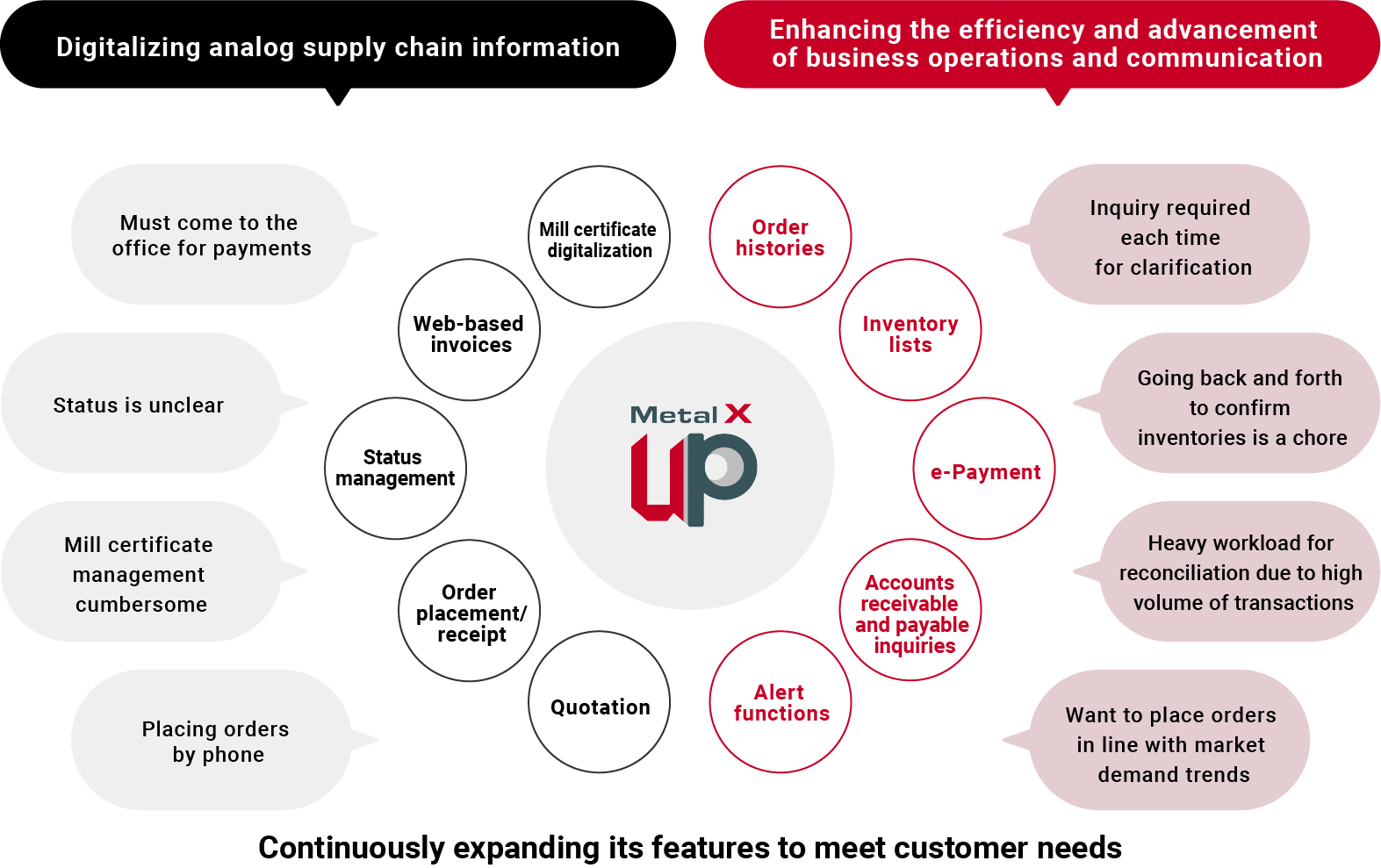

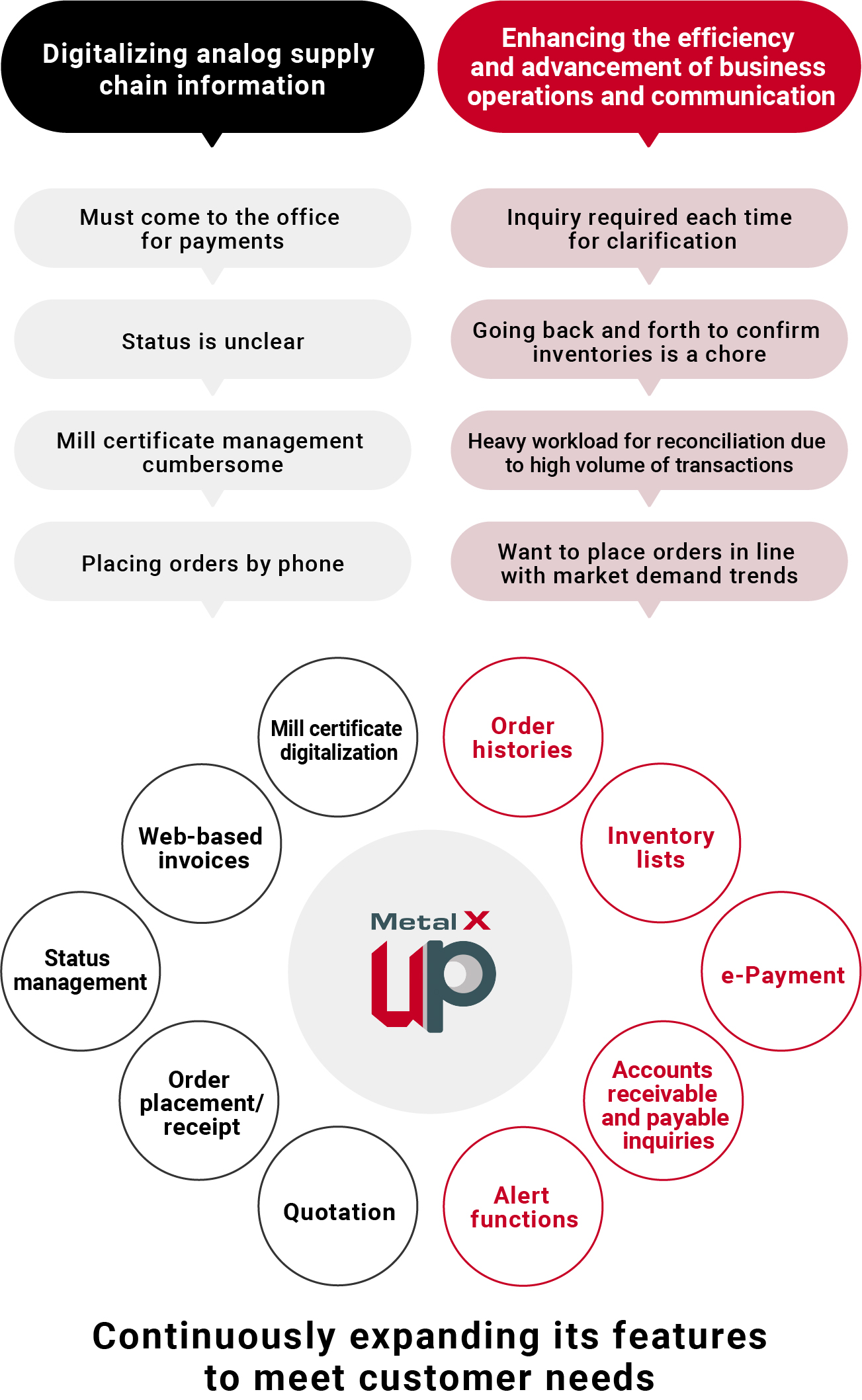

Metal X UP®

We are dedicated to developing and offering the communication platform “Metal X UP®” that aims to address various challenges in the steel supply chain. It is equipped with features such as the digitization of mill test certificates, enabling the transformation of analog information on the supply chain into digital format, as well as functionalities like automated reconciliation of accounts receivable and payable, and order history inquiry to enhance and advance business operations and communication. We have commenced offering this platform to the plate and sheet sectors. Undertaking additional expansion and enhancement of capabilities in future, we will be striving to be able to provide services to as many customers as possible, regardless of product type.

Strengthening IT and digital infrastructure

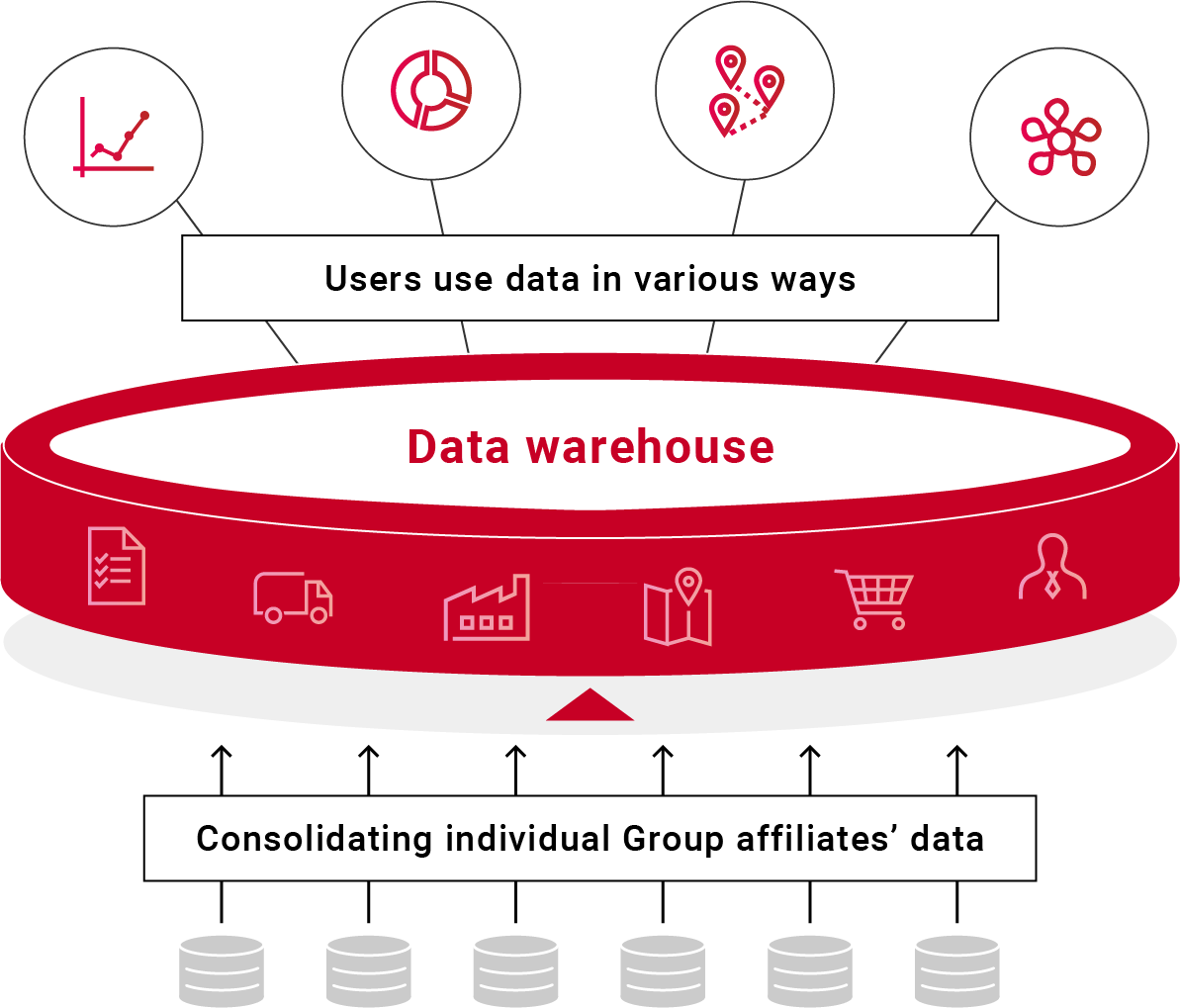

Data warehouse

As the foundation for Lean Operations and Solution Businesses, we are actively working on building a Data Warehouse that centralizes and enables the utilization of data held by the Group in one place. Currently, we are advancing the construction of various dashboards, standardizing code masters, and implementing automatic data conversion functionalities to progressively expand the scope of usable data.

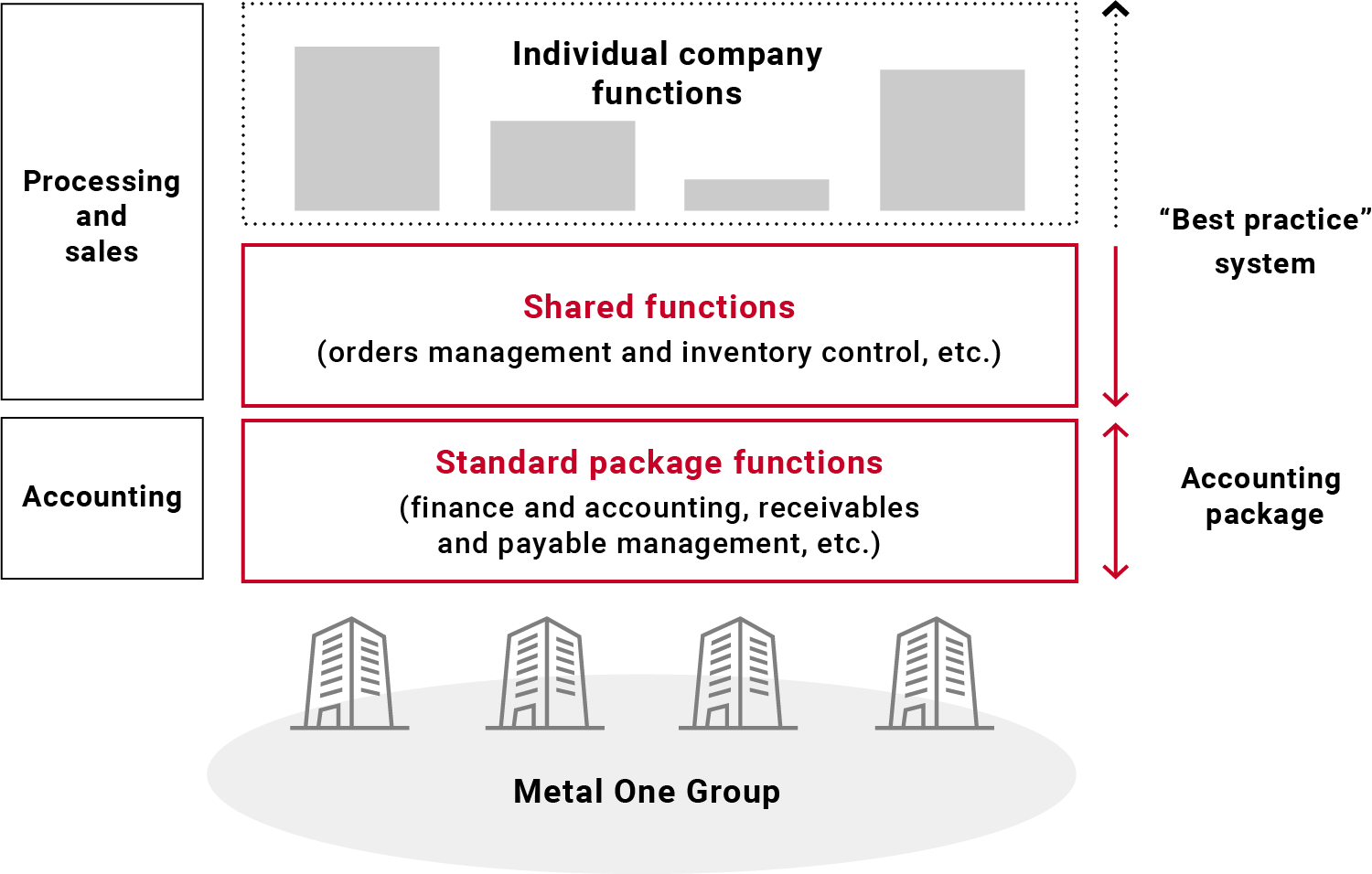

Standardizing ERP systems within the Group

With the aim of improving efficiency and standardization across our processing, sales, and accounting operations as a trading company, we are actively pursuing the group-wide standardization of ERP systems. In the non-competitive accounting domain, we are implementing thorough rationalization using external standard packages, while in the competitive processing and sales domain, we are deploying Metal One Group’s best practices as standard systems to establish a highly lean system foundation.

Organization to promote digital transformation

Promoting digital transformation through a Group-wide organization

To promote our digital transformation efforts, we have established a company-wide cross-functional structure, including Group companies. Through a Steering Committee involving the CEO and most of the executive management, we facilitate rapid decision-making and foster cross-departmental collaboration and leadership for numerous projects and initiatives. Under the direct supervision of the Chief Digital Officer (CDO), we have established the Transformation Management Office (TMO) as a core organization to drive DX initiatives across the entire company.

Training digital transformation personnel

Metal One is training personnel to drive digital transformation. This training is not limited to simply acquiring IT and digital skills; we are also devising training programs and frameworks that encourage growth so that personnel use digital technologies to create new businesses and reform our business model. These training programs do not just focus on classroom lectures, either. The digital transformation scene is filled with growth opportunities, including taking part in planning company-wide digital transformation projects and putting them into practice.

Training program examples

01. Joint programs

We have made joint programs available because we believe that digital transformation is something that most employees will be promoting and participating in. Our goal is to help employees understand and follow philosophies and methods for solving issues using digital technologies, such as through developing applications with no-code tools as well as cultivating a mindset oriented toward digital transformation. As of year 2023, around half our employees had finished or were scheduled to enroll in these joint programs. We also held a contest to develop applications designed to solve issues in operations that employees were personally involved in, among other things.

02. Programs for select and recruited personnel

Multiple programs for select and recruited personnel exist that enable them to spearhead business creation and digital transformation projects. Our various programs include a four-month program in which participants work on prototype development after learning the basics of IT, digital technology and business creation; a six-month program to acquire the skills needed to develop new businesses through a series of business creation processes; and a program that seeks to create businesses for the era of digital transformation by “deframing”—breaking down and rearranging existing frameworks.

03. Online studies

Using an online studies platform, Udemy Business, with a full lineup of IT and digital technology sector content, we provide an environment in which all employees—including the president and other executives—can study and grow independently. Providing recommended and designated courses related to digital technology, the company provides support for individuals to enhance existing skills and acquire new one for adapting to new duties.