-

-

Metal One’s businesses and roles

-

Plate, Construction & Tubular Products Business Division

-

Flat Products Business Division

-

Global Business Division

-

Global Marketing & Energy Project Business Division

-

Wire, Specialty & Stainless Steel Business Division

-

Digital transformation

-

Carbon neutrality

-

Business creation and innovation

-

-

Recruiting information

-

Terms of Use

News release

News release

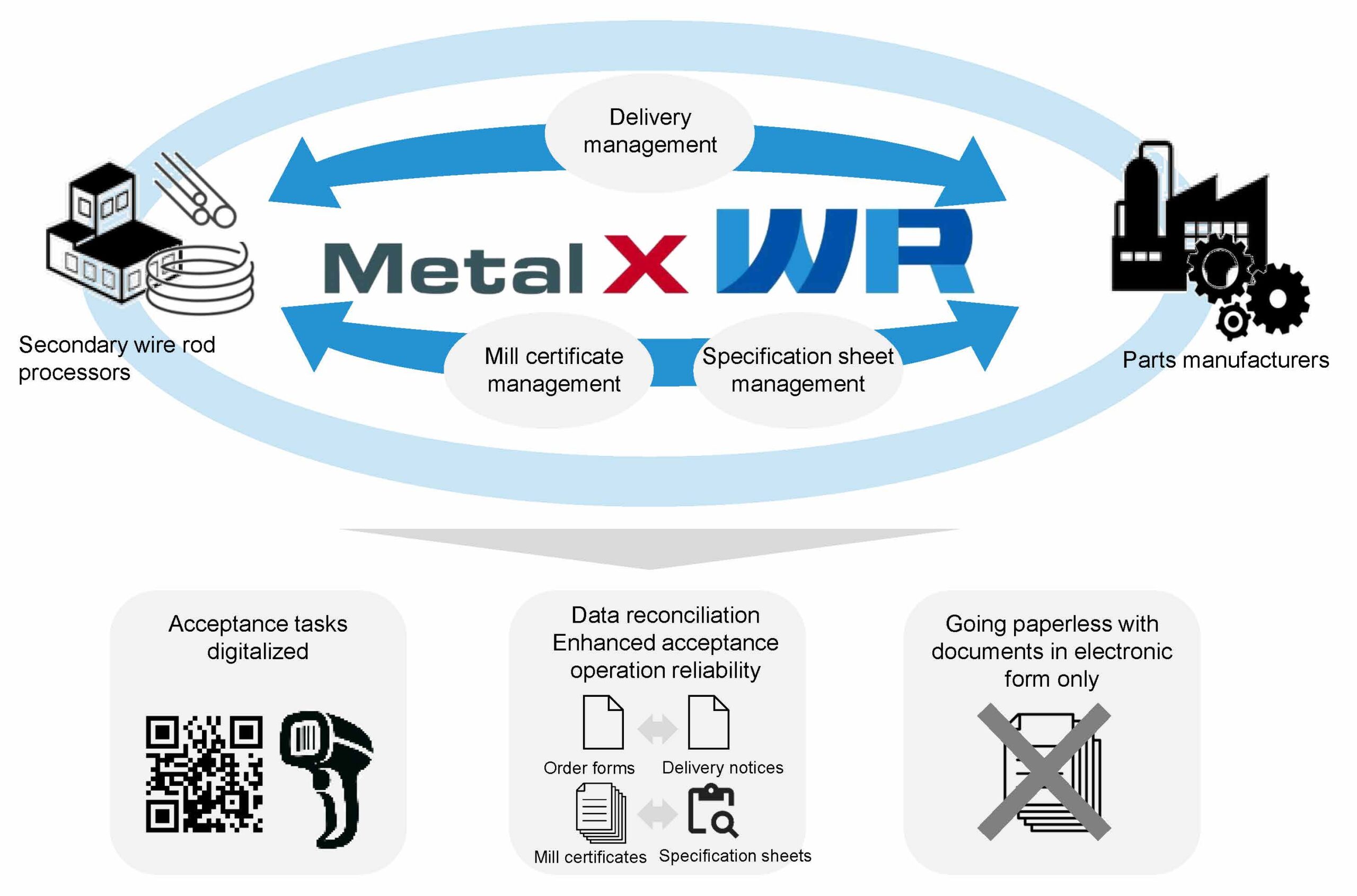

Metal X WR Services for Steel Wire Rod Processors and Parts Manufacturer Begin

~ Digitalizing the Workplace by Integrating Product Operations with Digital Systems ~

This is to announce that Metal One (headquartered in Chiyoda-ku, Tokyo; President: Yoshiyuki Watanabe) has devised Metal X WR—the third phase of our Metal X series—and began providing related services in June 2025.

The Metal X WR platform enhances the reliability of product purchasing and receiving operations by digitalizing data workflows. It also enables digital communication between steel wire rod processors and parts manufacturers within the supply chains of wire and specialty steel products.

Many key operational and administrative tasks in transactions between steel wire rod processors and parts manufacturers still rely on analog methods such as visual checks, handwritten memos and manual data input for order and delivery reconciliation. These tasks often involve visual inspections upon product receipt, and matching mill certificates (inspection result sheets) with their corresponding specifications, as well as handling acceptance forms. These manual processes are growing concerns due to labor shortages.

In response to these issues, Metal X WR allows users to meticulously manage respective wire and specialty steel transactions—which are typically small lots of multiple product items—with detailed controls for such things as chemical composition and mechanical properties. Additionally, the use of QR codes and the integration of technologies that connect physical products with digital systems streamlines operations for parts manufacturers by supporting digitalization and improving the reliability of purchasing processes.

During this initial stage we will be releasing functions for delivery management, mill certificate management, and specification sheet management.

With regard to delivery management, digitalizing parts manufacturers’ receiving operations for steel materials will significantly reduce the time required for these tasks and prevent human error, vastly improving reliability. This will also halt deliveries of products that deviate from specifications, since the system reconciles mill certificates issued by steel wire rod processors and the specification sheets that steel wire rod processors and parts manufacturers have agreed upon.

Metal X WR’s management function consolidates the management of mill certificates typically handled using paper or shared drives, and enhanced searchability broadly improves operational efficiency. Data use is also enhanced because both PDF files and the content of mill certificates (chemical composition, mechanical properties, and such) are stored. And since data storage in paper form is no longer necessary, CO2 emissions are also reduced.

The specification sheet management function is set up so that the system manages all specifications that secondary processors and parts manufacturers agree upon. Besides enhancing readability, the system makes it possible to reconcile mill certificate data with the content of specifications saved as data on the system.

Metal One Group affiliate Sunrock Oyodo Co., Ltd. developed Metal X WR in cooperation with that company’s parts manufacturer business partners in a bid to solve end-user issues. We will be developing services aligned with even more user requirements, implementing additional functional expansions and enhancements to serve as a comprehensive platform that resolves user issues.

Metal One believes that working on industry-wide digitalization, including at its Group companies, is necessary to resolve the steel industry’s issues. We are also proposing systems developed in-house such as the Metal X series to other companies, as well as to link to systems other companies have developed.

For more information, please contact:

Hajime Kimura or Toshiyuki Higuchi

Corporate Communications Unit, Corporate Administration, Safety & Health Department,

Metal One Corporation

Phone: +81-3-6777-2816 / Email: mo.pr@mtlo.co.jp